Removal and Installation

REMOVAL

| caution | Be sure that vehicle does not move before removing shift actuator.

|

1. Disconnect the negative battery terminal. Refer to Exploded View .

.

.

.2. Remove air duct and air cleaner. Refer to Exploded View .

.

.

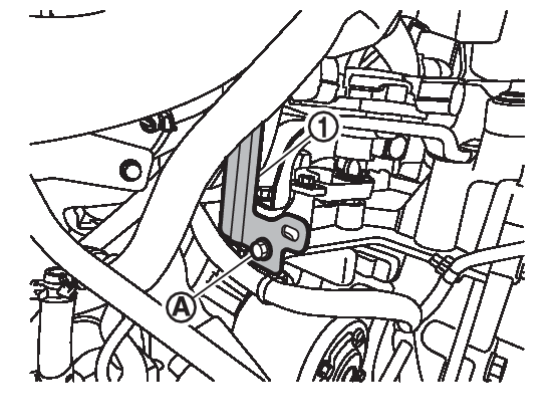

.4. Disconnect the harness connectors from the shift actuator.

INSTALLATION

| caution | Apply the parking brake. |

| caution | Note when the shift actuator is removed while the range is in the P position, and installed while the range is in the N position:

|

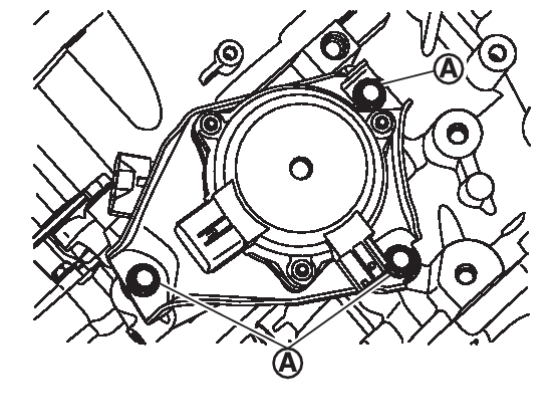

1. Clean splines of manual shaft and shift actuator before installing shift actuator.

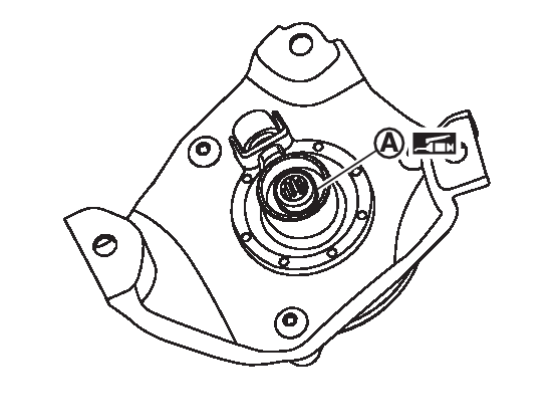

2. Apply grease evenly to the shift actuator spline  .

.

.

. | : Lithium-based grease including molybdenum disulphide |

3. Install the shift actuator to the transaxle assembly.

5. Connect the harness connectors to the shift actuator.

6. Install harness to bracket.

7. Install air duct and air cleaner. Refer to Exploded View .

.

.

.8. Connect the negative battery terminal. Refer to Exploded View .

.

.

.9. Turn the ignition switch ON and press the P position switch.

10. Turn the ignition switch OFF.

11. Perform inspection after installation. Refer to Inspection .

.

.

.![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)

.

.