System Description

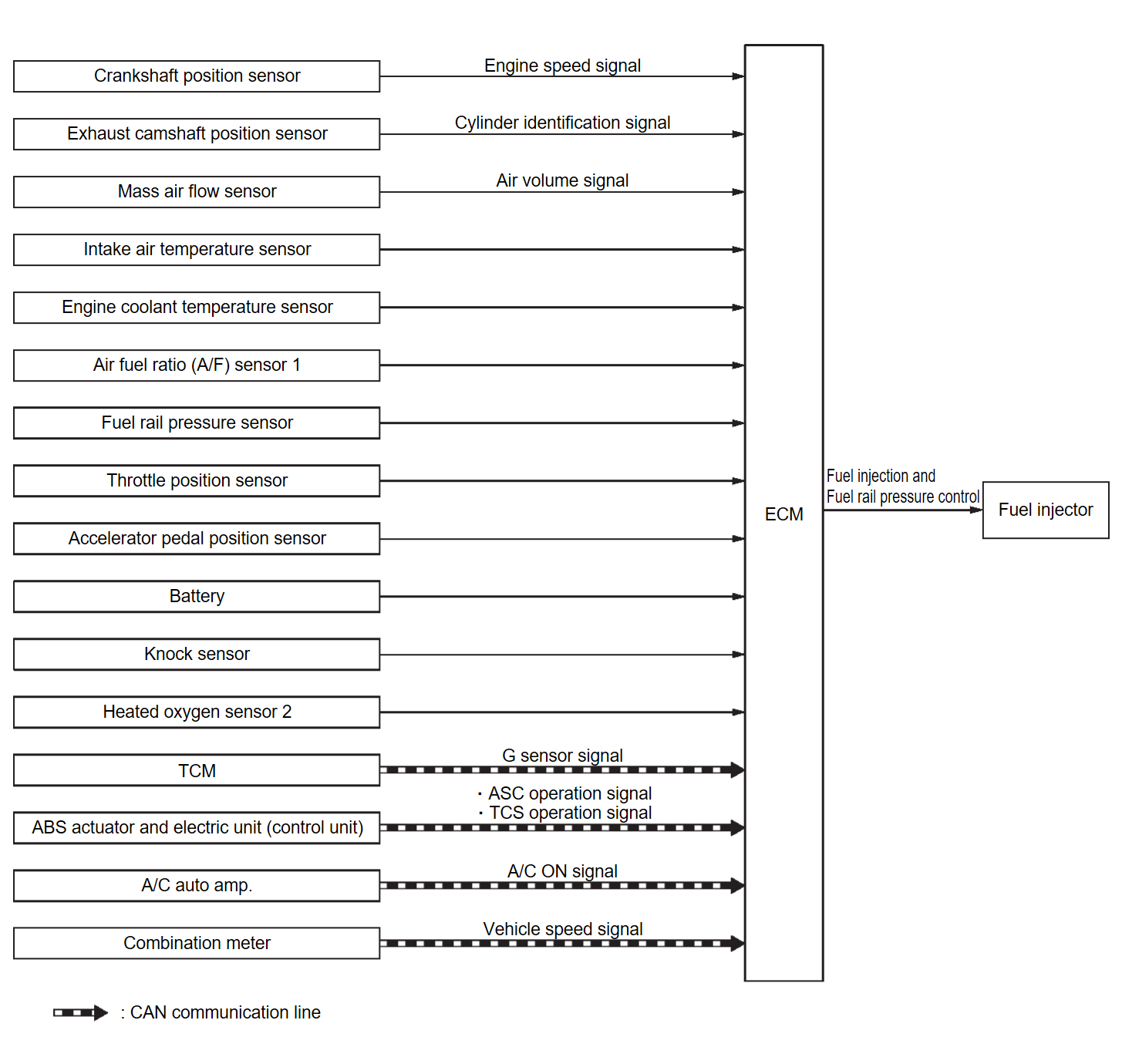

SYSTEM DIAGRAM

| Component parts | Function |

| Crankshaft position sensor | Crankshaft Position Sensor |

| Exhaust camshaft position sensor | Exhaust Camshaft Position Sensor |

| Mass air flow sensor (With intake air temperature sensor) | Mass Air Flow Sensor (With Intake Air Temperature Sensor) |

| Intake air temperature sensor | Mass Air Flow Sensor (With Intake Air Temperature Sensor) |

| Engine coolant temperature sensor | Engine Coolant Temperature Sensor |

| Air fuel ratio (A/F) sensor 1 | Air Fuel Ratio (A/F) Sensor 1 |

| Fuel rail pressure sensor | Fuel Rail Pressure Sensor |

| Throttle position sensor | Electric Throttle Control Actuator |

| Accelerator pedal position sensor | Electric Throttle Control Actuator |

| Battery | ECM receives the battery voltage signal. |

| Knock sensor | Knock Sensor |

| Heated oxygen sensor 2 | Heated Oxygen Sensor 2 . . |

| TCM | ECM receives the G sensor signal via CAN communication. |

| ABS actuator and electric unit (control unit) | ECM receives the following signals via CAN communication.

|

| A/C auto amp. | ECM receives the A/C ON signal via CAN communication. |

| Combination meter | ECM receives the vehicle speed signal via CAN communication. |

| ECM | ECM |

| Fuel injector | Fuel Injector |

SYSTEM DESCRIPTION

The adoption of the direct fuel injection system [DIG (Direct Injection Gasoline)] enables more accurate adjustment of fuel injection quantity by injecting atomized high-pressure fuel directly into the cylinder. This method allows high-powered engine, high torque, low fuel consumption, quietness, and emissions-reduction.

The amount of fuel injected from the fuel injector is determined by the ECM. The ECM controls the length of time the valve remains open (injection pulse duration). The amount of fuel injected is a program value in the ECM memory. The program value is preset by engine operating conditions. These conditions are determined by input signals (for engine speed and intake air and fuel rail pressure) from the crankshaft position sensor, camshaft position sensor, mass air flow sensor and the fuel rail pressure sensor.

FUEL INJECTION CONTROL

Injection Pattern

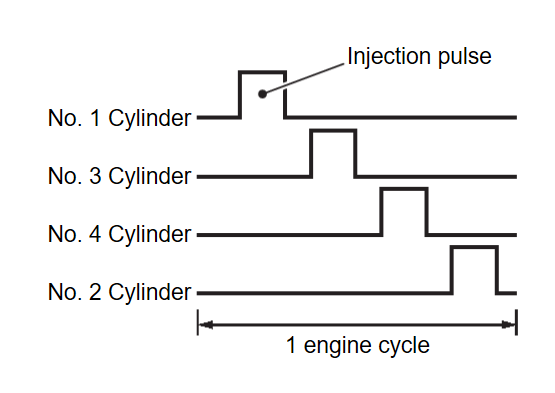

ECM conducts sequential injection (1 injection per 2 rotations of engine to each cylinder, suitable injection according to each cylinder's ignition order).

Injection when starting the engine

When starting the engine, ECM determines the amount of fuel injected according to conditions such as engine coolant temperature to make the starting smoother.

Also, conducts the starting control with stratified-charge combustion according to conditions.

Injection when driving normally

Normally, ECM determines the amount of injection to be an optimum air-fuel mixture ratio for homogeneous combustion.

Cut-in injection when acceleration

When accelerating, according to the opening speed of throttle valve, ECM conducts a cut-in injection adding to normal injection and improves accelerating performance.

DIRECT FUEL INJECTION CONTROL

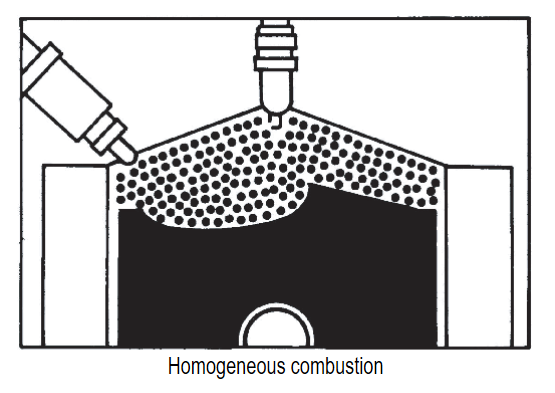

Homogeneous Combustion

Homogeneous combustion is a combustion method that fuel is injected during intake process so that combustion occurs in the entire combustion chamber, as is common with conventional methods. As for a start except for starts with the engine cold, homogeneous combustion occurs.

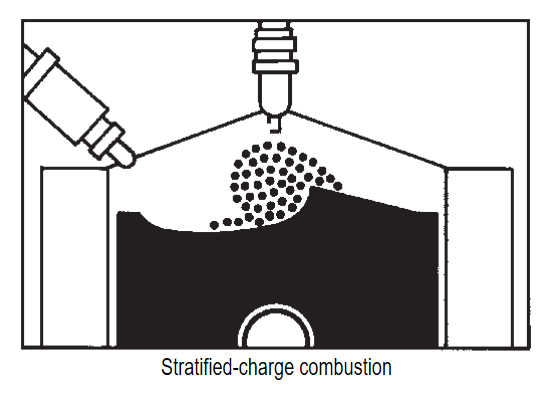

Stratified-charge Combustion

Stratified-charge combustion is a combustion method which enables extremely lean combustion by injecting fuel in the latter half of a compression process, collecting combustible air-fuel around the spark plug, and forming fuel-free airspace around the mixture. Right after a start with the engine cold, the catalyst warm-up is accelerated by stratified-charge combustion.

VARIOUS FUEL INJECTION INCREASE/DECREASE COMPENSATION

The amount of fuel injected is compensated to improve engine performance under various operating conditions as listed below.

<Fuel increase>

- During warm-up

- When starting the engine

- During acceleration

- Hot-engine operation

- When selector lever position is changed from N to D

- High-load, high-speed operation

<Fuel decrease>

- During deceleration

- During high engine speed operation

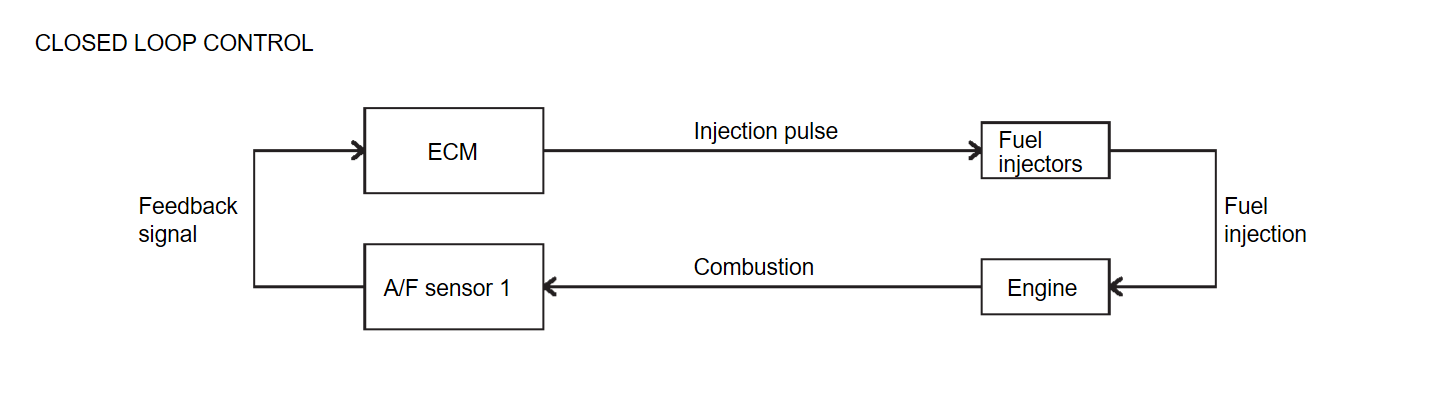

MIXTURE RATIO FEEDBACK CONTROL (CLOSED LOOP CONTROL)

The mixture ratio feedback system provides the best air-fuel mixture ratio for driveability and emission control. The three way catalyst (manifold) can better reduce CO, HC and NOx emissions. This system uses A/F sensor 1 in the exhaust manifold to monitor whether the engine operation is rich or lean. The ECM adjusts theinjection pulse width according to the sensor voltage signal. And the correcting factor to control the pulse width is displayed as “A/F CORRECTION”, or “S-FUEL TRM-B1 [%]”. For more information about A/F sensor 1, Refer to Air Fuel Ratio (A/F) Sensor 1 . This maintains the mixture ratio within the range of stoichiometric (ideal air-fuel mixture). This stage is referred to as the closed loop control condition.

. This maintains the mixture ratio within the range of stoichiometric (ideal air-fuel mixture). This stage is referred to as the closed loop control condition.

. This maintains the mixture ratio within the range of stoichiometric (ideal air-fuel mixture). This stage is referred to as the closed loop control condition.

. This maintains the mixture ratio within the range of stoichiometric (ideal air-fuel mixture). This stage is referred to as the closed loop control condition.Heated oxygen sensor 2 is located downstream of the three way catalyst (manifold). Even if the switching characteristics of A/F sensor 1 shift, the air-fuel ratio is controlled to stoichiometric by the signal from heated oxygen sensor 2.

Open Loop Control

The open loop system condition refers to when the ECM detects any of the following conditions. Feedback control stops (clamp) in order to maintain stabilized fuel combustion.

- Deceleration and acceleration

- High-load, high-speed operation

- Malfunction of A/F sensor 1 or its circuit

- Insufficient activation of A/F sensor 1 at low engine coolant temperature

- High engine coolant temperature

- During warm-up

- After shifting from N to D

- When starting the engine

MIXTURE RATIO SELF-LEARNING CONTROL

The mixture ratio feedback control system monitors the mixture ratio signal transmitted from heated oxygen sensor 1. This feedback signal is then sent to the ECM. The ECM controls the basic mixture ratio as close to the theoretical mixture ratio as possible. However, the basic mixture ratio is not necessarily controlled as originally designed. Both manufacturing differences (i.e., mass air flow sensor hot wire) and characteristic changes during operation (i.e., fuel injector clogging) directly affect mixture ratio.

Accordingly, the difference between the basic and theoretical mixture ratios is monitored in this system.This is then computed in terms of “injection pulse duration” to automatically compensate for the difference between the two ratios.

“Fuel trim” refers to the feedback compensation value compared against the basic injection duration. Fuel trimincludes short term fuel trim and long term fuel trim.

“Short term fuel trim” is the short-term fuel compensation used to maintain the mixture ratio at its theoretical value. The signal from heated oxygen sensor 1 indicates whether the mixture ratio is RICH or LEAN compared to the theoretical value. The signal then triggers a reduction in fuel volume if the mixture ratio is rich, and anincrease in fuel volume if it is lean.

“Long term fuel trim” is overall fuel compensation carried out long-term to compensate for continual deviation of the short term fuel trim from the central value. Such deviation will occur due to individual engine differences,wear over time and changes in the usage environment.

FUEL INJECTION TIMING

Fuel is injected into each cylinder during each engine cycle according to the ignition order.

STRATIFIED-CHARGE START CONTROL

The use of the stratified-charge combustion method enables emissions-reduction when starting with the engine cold.

FUEL SHUT-OFF

Fuel shut-off during deceleration

Fuel to each cylinder is cut off during deceleration for restraint of HC and improvement of fuel efficiency.

Engine speed at which fuel shut-off and recovery is conducted are programmed in detail according to various factors such as idle judgment, vehicle speed, gear position, engine coolant temperature etc. for optimizing emission and mileage performance.Also, no fuel shut-off is applied at extreme deceleration.

Fuel shut-off when the engine speed is excessively high

ECM shuts off fuel for all cylinders at the engine speed over 6,500 rpm, and recovers under 6,200 rpm.

Fuel shut-off when the engine speed is excessively high with no load

ECM shuts off fuel for all cylinders at the engine speed is high, and the vehicle speed is 0 km/h with N or P gear position for more than certain duration.

Fuel shut-off when the engine is over heating

ECM judges as the engine is over heating and conducts fuel shut-off when the output voltage of engine coolant temperature sensor exceeds the over heating judgment voltage for certain duration.

Also, malfunction indicator light (MIL) illuminates when the engine is judged as over heating.

And, once the engine over heating judgment is made, malfunction indicator light (MIL) remains ON even the engine coolant temperature becomes low (returns to normal), then fuel will be shut off at 2,000 rpm.

Fuel shut-off will be deactivated when the ignition key is turned OFF once, but malfunction indicator light (MIL) remains ON. The deactivation of malfunction indicator light (MIL) can be done by clearing self diagnosis results.

| caution | Erase self diagnosis results only after the investigation of the engine over heating cause. |

Fuel shut-off when N → D position is selected

Fuel shut-off is conducted when the engine speed is high and N → D position is selected.

Fuel shut-off when the engine stalls consecutively

To protect CVT, ECM conducts fuel shut-off when the engine speed is high despite the vehicle speed is excessively slow for more than several minutes with gear position except N or P. This control is not conducted when the malfunction of vehicle speed signal exists.

Fuel shut-off when malfunction indicator light (MIL) system is not working

ECM warns driver by conducting fuel shut-off when the request to illuminate malfunction indicator light (MIL) due to some of the self diagnosis relating electric throttle system or ECM continuously exist for more than 5 trips. ECM shuts off fuel at approx. 2,500 rpm and recovers at approx. 2,000 rpm.

Fuel shut-off when the throttle stuck to closed position

ECM conducts fuel shut-off when the electric throttle is stuck to its closed position.

But, for the sake of heating capability, ECM allows the engine start at N or P gear position with limited engine speed.

![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)