DTC Diagnosis Procedure

2.CHECK VTC POSITION

With M.U.T.-III SE

With M.U.T.-III SE- Turn ignition switch ON.

- On the M.U.T.-III SE screen, select “ENGINE” >> “DATA MONITOR” >> “COOLANT TEMP/S”.

- Check that the “COOLANT TEMP/S” indication value is between −5°C (23°F) and 45°C (113°F).

- Start engine and wait at least 5 seconds.

- On the M.U.T.-III SE screen, select “ENGINE” >> “DATA MONITOR” >> “EXH/V TIM B1”.

- Check that the data monitor item indicates as follows:

Item Value (°CA) EXH/V TIM B1 10 ± 2

Is the inspection result normal?

Check intermittent incident. Refer to Intermittent IncidentIntermittent Incident

Check intermittent incident. Refer to Intermittent IncidentIntermittent Incident .

.4.CHECK EXHAUST VALVE TIMING INTERMEDIATE LOCK CONTROL SOLENOID VALVE

Perform Component Inspection of the exhaust valve timing intermediate lock control solenoid valve. Refer to Component Inspection .

. Repair or replace error-detected parts.

Repair or replace error-detected parts.

.

.Is the inspection result normal?

Repair or replace error-detected parts.

Repair or replace error-detected parts.5.CHECK EXHAUST VALVE TIMING CONTROL SOLENOID VALVE

Perform Component Inspection of the exhaust valve timing control solenoid valve. Refer to Component Inspection .

. Repair or replace error-detected parts.

Repair or replace error-detected parts.

.

.Is the inspection result normal?

Repair or replace error-detected parts.

Repair or replace error-detected parts.6.CHECK CRANKSHAFT POSITION SENSOR

Perform Component Inspection of the crankshaft position sensor. Refer to Component InspectionComponent Inspection (Crankshaft Position sensor) .

. Repair or replace error-detected parts.

Repair or replace error-detected parts.

.

.Is the inspection result normal?

Repair or replace error-detected parts.

Repair or replace error-detected parts.7.CHECK EXHAUST CAMSHAFT POSITION SENSOR

Perform Component Inspection of the exhaust camshaft position sensor. Refer to Component Inspection .

. Repair or replace error-detected parts.

Repair or replace error-detected parts.

.

.Is the inspection result normal?

Repair or replace error-detected parts.

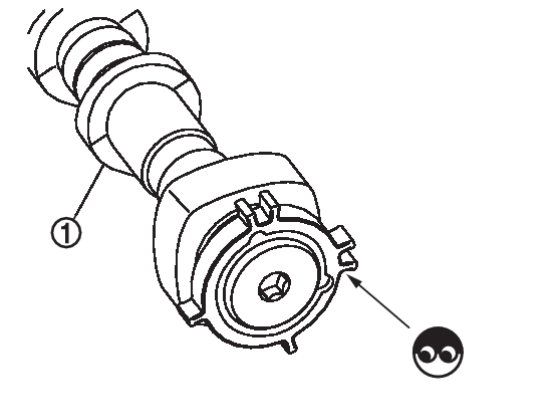

Repair or replace error-detected parts.8.CHECK CAMSHAFT (EXHAUST)

Check the following. Remove debris and clean the signal plate of camshaft front end or replace camshaft. Refer to Removal and Installation

Remove debris and clean the signal plate of camshaft front end or replace camshaft. Refer to Removal and Installation .

.

- Accumulation of debris on the signal plate of camshaft

front end

front end - Chipping signal plate of camshaft front end

Is the inspection result normal?

Remove debris and clean the signal plate of camshaft front end or replace camshaft. Refer to Removal and Installation

Remove debris and clean the signal plate of camshaft front end or replace camshaft. Refer to Removal and Installation .

.9.CHECK TIMING CHAIN INSTALLATION

Check service records for any recent repairs that may cause timing chain misalignment. Check timing chain installation. Refer to Removal and Installation

Check timing chain installation. Refer to Removal and Installation .

.

Are there any service records that may cause timing chain misalignment?

Check timing chain installation. Refer to Removal and Installation

Check timing chain installation. Refer to Removal and Installation .

.10.CHECK LUBRICATION CIRCUIT

Perform “Inspection of Camshaft Sprocket (EXHAUST) Oil Groove”. Refer to Inspection .

. Check intermittent incident. Refer to Intermittent IncidentIntermittent Incident

Check intermittent incident. Refer to Intermittent IncidentIntermittent Incident .

. Clean lubrication line.

Clean lubrication line.

.

.Is the inspection result normal?

Check intermittent incident. Refer to Intermittent IncidentIntermittent Incident

Check intermittent incident. Refer to Intermittent IncidentIntermittent Incident .

. Clean lubrication line.

Clean lubrication line.![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)