Inspection

INSPECTION AFTER REMOVAL

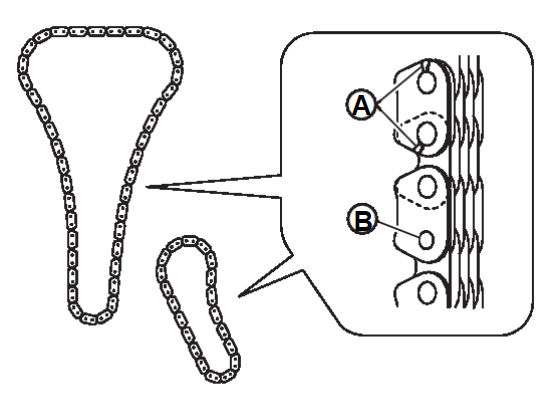

Timing Chain

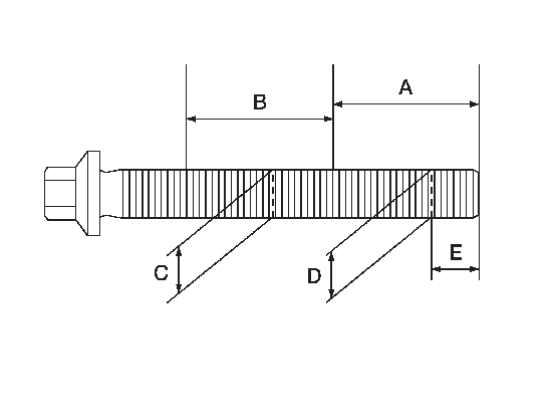

Balancer Unit Bolt Outer Diameter

INSPECTION AFTER INSTALLATION

Inspection for Leaks

The following are procedures for checking fluids leak, lubricates leak.

- Before starting engine, check oil/fluid levels including engine coolant and engine oil. If less than required quantity, fill to the specified level. Refer to Fluids and Lubricants

.

. - Use procedure below to check for fuel leakage.

- Turn ignition switch “ON” (with engine stopped). With fuel pressure applied to fuel piping, check for fuel leakage at connection points.

- Start engine. With engine speed increased, check again for fuel leakage at connection points.

- Run engine to check for unusual noise and vibration.

- Warm up engine thoroughly to check there is no leakage of fuel, or any oil/fluids including engine oil and engine coolant.

- Bleed air from lines and hoses of applicable lines, such as in cooling system.

- After cooling down engine, again check oil/fluid levels including engine oil and engine coolant. Refill to the specified level, if necessary.Summary of the inspection items:

Items Before starting engine Engine running After engine stopped Engine coolant Level Leakage Level Engine oil Level Leakage Level Transmission / transaxle fluid Leakage Level / Leakage Leakage Other oils and fluids* Level Leakage Level Fuel Leakage Leakage Leakage Exhaust gases — Leakage — *: Power steering fluid, brake fluid, etc.

![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)

and any excessive wear

and any excessive wear  at the roller links of timing chain. Replace timing chain if necessary.

at the roller links of timing chain. Replace timing chain if necessary.